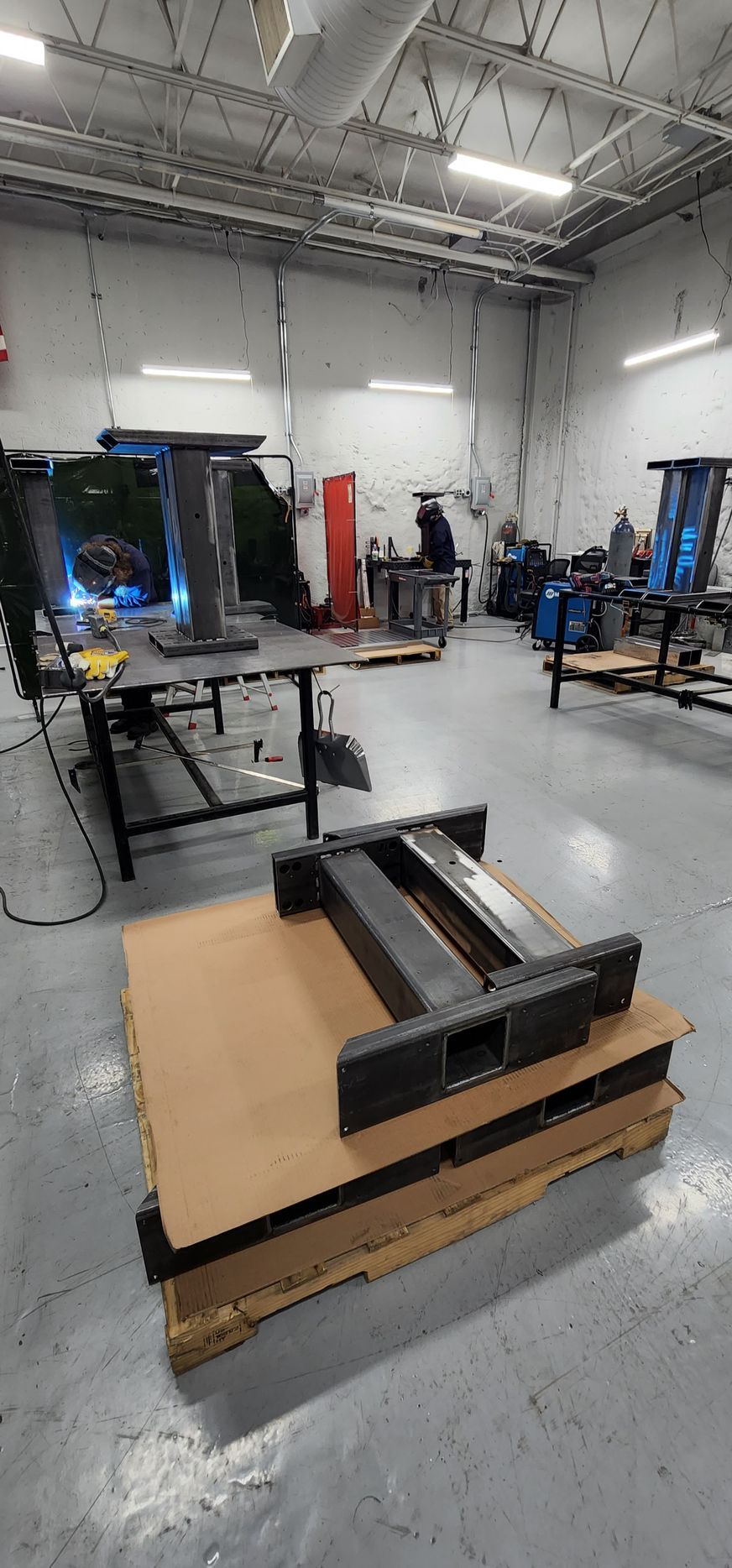

STEEL

From steel sheets to steel structures - we've got you covered.

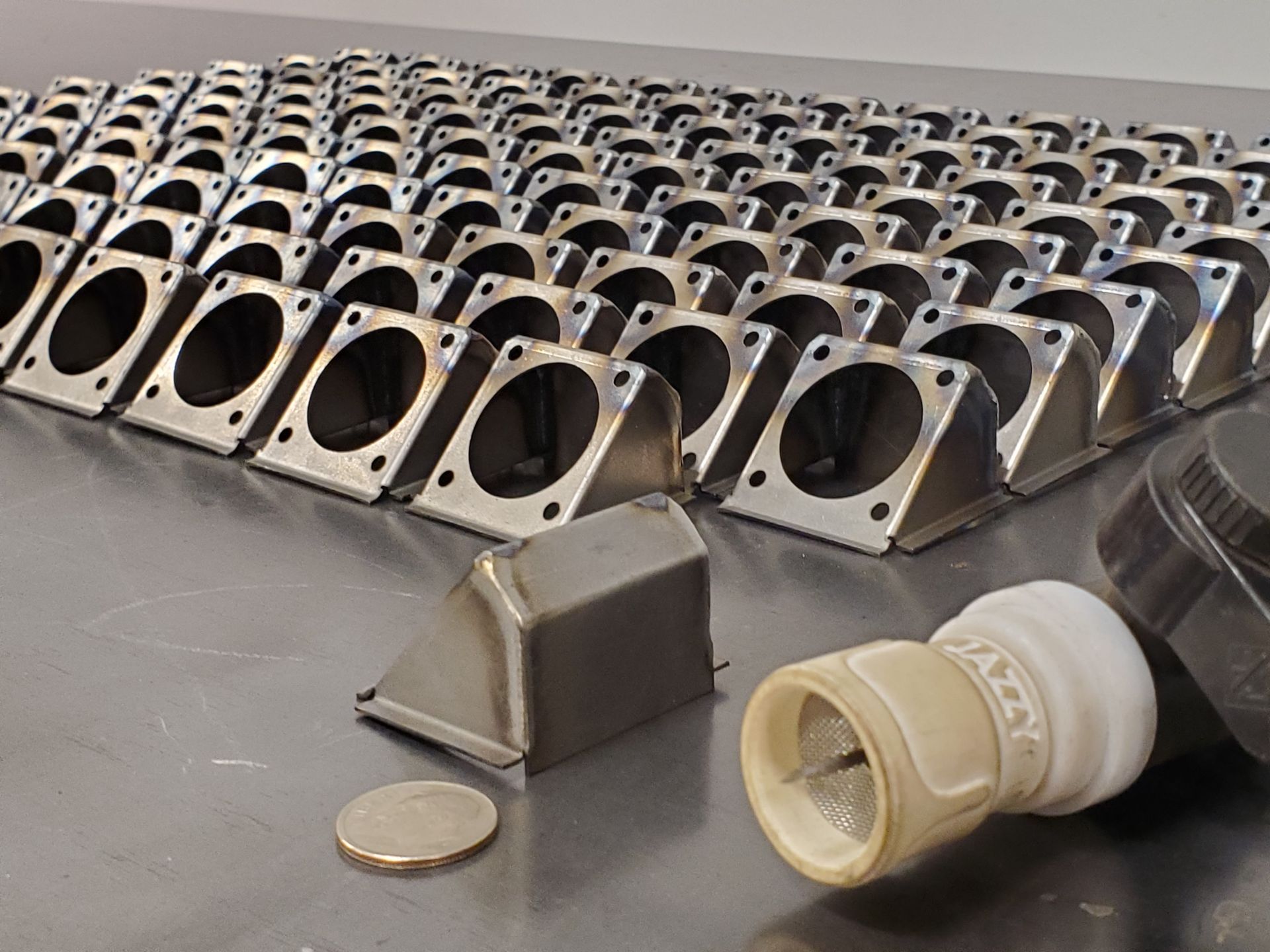

Steel welding is a vital process used in many industries to create high-quality metal structures. Welding steel is a complex task that requires specialized knowledge and expertise. We have a deep understanding of metallurgy, welding techniques, and safety protocols to ensure our work meets the specific requirements of each project.

One of the primary challenges of welding steel is the high temperatures involved in the process. Steel has a very high melting point, which means we must use high heat and precise control to create a strong, durable weld. We also take into account factors such as the thickness and composition of the steel, as well as the desired appearance and performance of the finished product.

To ensure that welds meet the highest standards for strength and durability, we use a variety of techniques and equipment. Some of the most common techniques used in steel welding include MIG welding, TIG welding, stick welding, and flux-cored welding. Each technique has its own advantages and disadvantages, so we choose the right method for the specific requirements of each project.

Despite the challenges of steel welding, it remains an essential process for creating high-quality metal structures. From building bridges and skyscrapers to manufacturing machinery and vehicles, welding steel is a critical component of many industries. With the right training, equipment, and expertise, we produce some of the strongest and most reliable steel structures in the world.