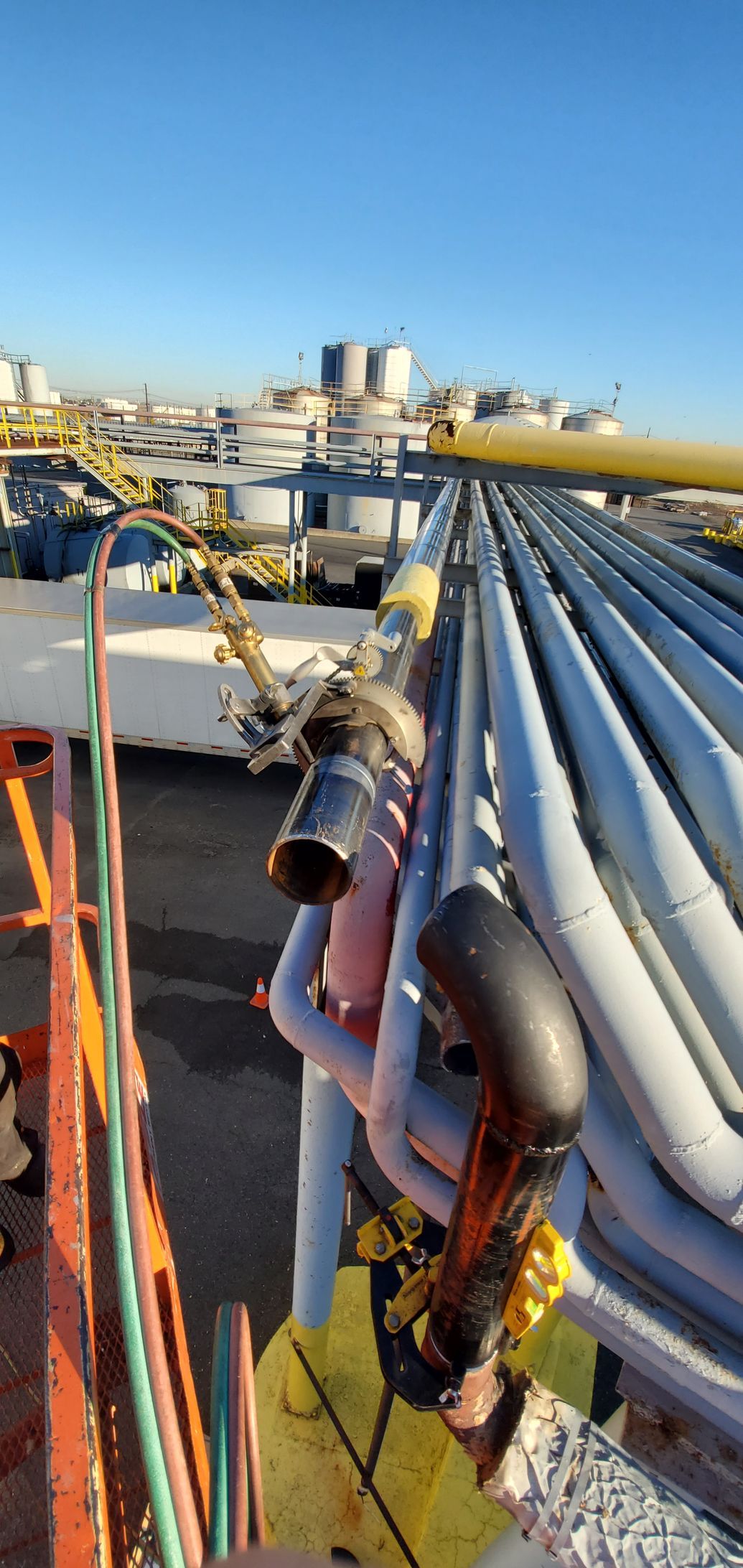

PIPING

Strong, seamless, and built to last: Welding pipes with precision and expertise.

Welding piping is the process of joining two or more sections of pipes together using heat and pressure to create a continuous, leak-free connection. Welding is one of the most common methods of joining pipes in various industries, including oil and gas, water treatment, and construction.

There are several different types of welding techniques that can be used for welding piping, including:

- Shielded Metal Arc Welding (SMAW): Also known as stick welding, this process uses a consumable electrode coated in flux to create an electric arc that melts the base metal and fuses it together.

- Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, this process uses a non-consumable tungsten electrode and a shielding gas to create an electric arc that melts the base metal and fuses it together.

- Gas Metal Arc Welding (GMAW): Also known as MIG (Metal Inert Gas) welding, this process uses a consumable wire electrode and a shielding gas to create an electric arc that melts the base metal and fuses it together.

- Flux-Cored Arc Welding (FCAW): This process uses a flux-cored wire electrode that contains flux to shield the weld from atmospheric contamination, making it suitable for outdoor welding.

The selection of the welding process and equipment will depend on several factors, including the type of pipe material, its thickness, and the application requirements. Additionally, it is crucial to prepare the pipe surfaces properly by cleaning and beveling the edges to ensure a strong and consistent weld.

Welding piping is an essential process in many industries, and proper welding techniques and procedures are critical to ensuring the safety and reliability of the finished product. It is important to follow industry standards and guidelines, as well as any applicable regulations, to ensure that the welding is performed correctly and the finished product meets the necessary standards for the intended application.